All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).

10%wt co-processing of fast pyrolysis bio-oil in a conventional fluidized catalytic cracking unit in an existing refinery

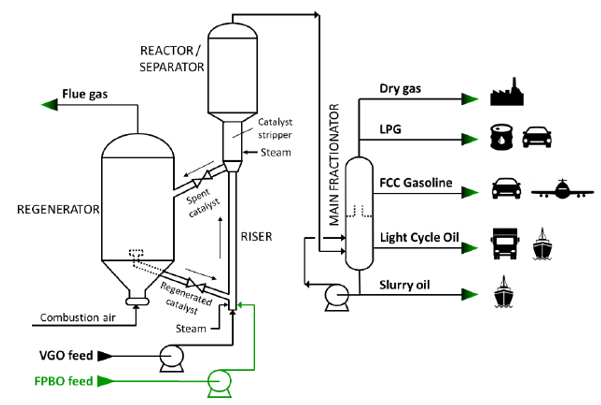

There is the possibility of processing fast pyrolysis bio-oil (FPBO) in existing refineries. The most studied application currently is to co-process the bio-oil together with vacuum gasoil (VGO) in a FCC unit (fluidized catalytic cracking), which is normally present in complex refineries. FPBO is injected into the riser from a separate feed line in order to keep its temperature below 60˚C. In the riser, the FPBO is catalytically cracked together with the VGO (or other regular FCC feed). The biocarbon in the FPBO is distributed across the various FCC products and the coke. The resulting products are a mix of fossil and biofuels, gasoline and diesel being the main outputs. As in a conventional FCC, the coke deposits on the catalyst, which is burned in the regenerator. This combustion supplies the energy required for the cracking reactions. Worldwide experiments claim that minor changes in the product yields are noticed in the FCC with co-processing up to 10%wt bio-oil. Few additional installations are needed to the refineries due to the acidity of the pyrolysis bio-oil, new pipelines, feed nozzle and storage tank would be necessary. The investment costs reported in this factsheet are, therefore, related only to the new units, e.g., additional costs. Picture was extracted from Lammens, T., Talebi, G., Gbordzoe, E. (2019).

Downloads

10%wt co-processing of fast pyrolysis bio-oil in a conventional fluidized catalytic cracking unit in an existing refineryGerelateerde publicaties

Industriële vraagrespons: groot potentieel, beperkte operationele inzetbaarheid

Wat industriële vraagrespons wel en niet kan betekenen voor leveringszekerheid richting 2030

Flexibiliteit op bedrijventerreinen

Een toekomstverkenning van het potentieel van energieassets

Kosten hernieuwbare energie verrassend vergelijkbaar voor Nederlandse en Saoedi-Arabische industrie

Comparison of future cost of renewable energy between regions