The bio-oil resulting from pyrolysis is acidic, corrosive, high in oxygen and moderate in water content. Details of the pyrolysis bio-oil production via fast pyrolysis of woody biomass can be found at Oliveira (2020). Therefore, the raw bio-oil is not suitable for direct mixing with fossil oils and cannot be used for engines without upgrading it to a fuel with similar properties as more conventional liquid fuels (JRC, 2019). The Pyrolysis bio-oil upgrading route is currently being developed, some in an earlier stage and others in a more advanced stage of development. These treatments involve putting the bio-oil in contact with a large excess of hydrogen in the presence of a catalyst. The raw bio-oil can be directly upgraded in a hydrodeoxygenation unit integrated with the pyrolysis plant facility. The process aims to reduce or eliminate oxygen, sulphur and nitrogen content in the bio-oil, with the use of hydrogen. The resulting streams of this process are a gas rich in light hydrocarbons and carbon dioxide, an aqueous phase and the deoxygenated bio-oil (PNNL, 2013).

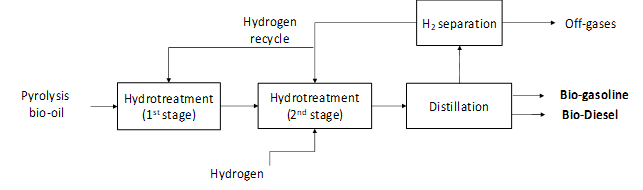

The upgrading system is composed by a two stage hydrotreatment process, the first stage is carried under mild temperature (180-250 ˚C) and the second one operates in more severe conditions (350-425 ˚C) (PNNL,2013). This scheme is reported in literature to prevent catalyst coking and allow higher yields than systems with single hydrotreatment (PNNL,2013). The upgraded bio-oil can reach an oxygen concentration below 2% vol., which can be directly processed in a distillation column in order to recover products such as bio-naphtha and bio-diesel. The off-gases pass through a PSA (pressure swing adsorption) unit in order to recover the remaining hydrogen and recycle it back to the hydrotreatment reactors. The remaining gases can be used as fuel or for hydrogen production in a SMR (steam methane reformer), however, none of these options are included in the scope of this factsheet. For this reason, the off-gases are considered as a by-product of the system. Extra hydrogen is needed and, in this process scheme, it is assumed that this hydrogen is outsourced. The extra steam and electricity produced in the fast pyrolysis unit can be utilized by the upgrading system since both processes are considered to be integrated. This facsheet considers only the upgrading system without the pyrolysis bio-oil production unit.

All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).