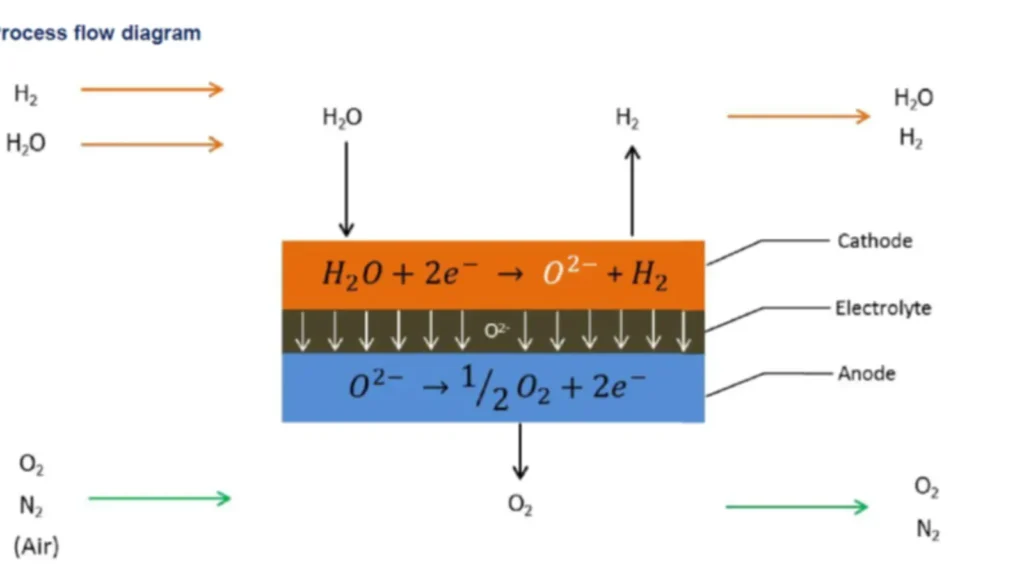

Solid-oxide electrolyzers are most commonly used high-temperature electrolyzers [5] but it is also the least developed electrolysis technology [2]. Solid-oxide electrolysers operate between 650-1000 °C and already offer impressively higher efficiency level (93%, higher heating value (HHV)) than other electrolyzers [3]. The electrical efficiencies could be increased up to 97 % (HHV) by integrating derived heat and thermal coupling to exothermal processes such as chemical methanation [3].

Broadly, there are two categories of SOEC: electrolyte supported (operating temperature > 800 °C) and anode supported (operating temperature 600 -850°C). As it mainly requires ceramics and few rare materials for the catalyst layer, It has a substantial cost reduction potential in the future [6]. Yet, the need for external high-temperature heat source (preferably from renewables such as concentrated solar power (CSP) or geothermal or industrial waste heat) at vincinity also provides challenges to its economic viability [6].

However, It can, in principle, also be operated without external high-temperature heat sources by using heat recovery, high-efficiency insulation, and compensating heat losses from electrical heating. Despite high capacity and efficiency, the electrolyser currently has reached life-time of 25000 operation hours and technology improvements such as stabilising components materials, developing new materials and lowering the operation temperature (500 -700 C) are being done to improve it further [2]. Current capacities of operational SOEC system are in the range lower than 1 MW, however, a 2.6 MW SOEC system is currently being developed in Rotterdam within the framework of H2020 MULTIPLHY [7].

All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).