Working of the Technology

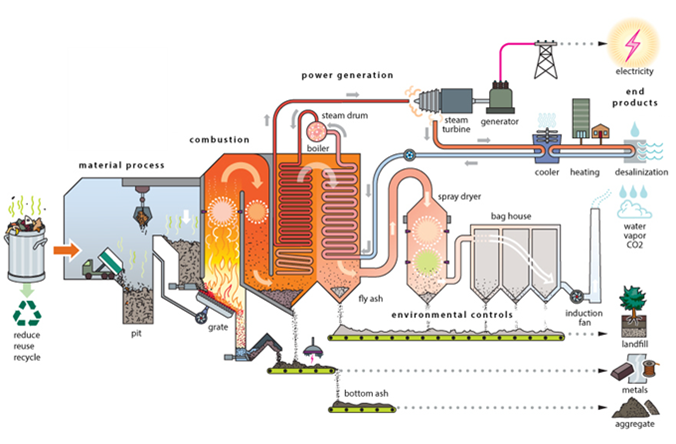

A waste incinerator or waste-to-energy plant can be a combined-heat and power-plant (CHP). Water is evaporated in a boiler to produce high pressure steam which is expanded in a turbine to generate electricity using a generator. Cooling water cools down the water that has passed through the turbine. From the drain of the steam turbine heat can be fed into a heat network. Heat can be supplied to different sectors such as the built environment, industry or horticulture. This factsheet focuses on a waste CHP plants connected to a heat network. A waste incinerator without CO2 capture and storage (CCS) is considered in this factsheet.

In most cases, waste-to-energy plants are utilised to burn a mixture of municipal solid waste (MSW) and company waste.

The waste incinerator technology generally employs moving grate furnaces (ETRI, 2014).

Main Components

The main technological components of a waste incinerator consist of a waste bunker, cranes, furnace, ash storage bunkers, boiler, fly ash handling equipment, slag handling equipment and wet gas washing equipment. Waste incinerators are also equipped with advanced flue gas cleaners to prevent or limit the emission of various possibly harmful substances, amongst others: PM, VOC, NOx, NH3, SO2. Flue gas cleaners are included in the costs presented in this factsheet.

Energy production related aspects

The waste mixture is partly biogenic which results in a lower CO2 emission factor (kgCO2/GJ heat supplied) compared to heat produced by fossil fuel-fired CHP plants (ECN, 2017c; CE, 2016; Ecofys, 2014).

The downside of utilizing heat for district heating is that it lowers the electrical efficiency of CHP plants (loss of electricity production). Typical losses are given in this factsheet.

It is also important to note that the energy produced by waste incinerators is a by-product of waste treatment (Ecofys, 2014). This means that the amount of energy produced can be higher or lower depending on waste availability and that the level of energy produced will not necessarily follow energy demand. Last but not least, heat and electricity output can be controlled and can vary depending on the season.

All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).