All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).

Geothermal heat production, deep, (>1500 < 4000 meter)

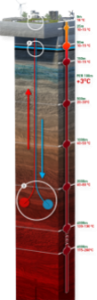

This technology represents the application of heat production from geothermal formations in The Netherlands. A typical project consists of two wells, a production and an injection well, also called doublet. The wells are either fully vertically drilled or vertical with a curvature deep below. The bottom of the wells is situated in a water holding layer of sand- or limestone, and lies between 1500 and 4000 meters below ground level. Salty hot water (brine) is pumped up through the production well, cooled in a heat exchanger and injected back underground through the injection well. In principle there is no loss of brine water, but some degassing may be needed as natural gas may be dissolved in the brine and needs to be separated. An alternative is to maintain sufficient pressure so that no natural gas escapes and is injected back underground. The warm water production temperature varies typically between 70 and 90⁰C (max 100⁰C) depending on the depth and the type of layer. For the Netherlands, a temperature gradient of around 30⁰C per kilometer is valid. The injection temperature lies between 35⁰C or lower. Lowering the injection temperature can increase the heat output of the system. Production volumes can be several hundreds m3 per hour, depending on the heat demand and the well characteristics. The installation consists of two bore holes usually in steel with liners, a production pump (Electric Submersible Pump, ESP), an above ground heat exchanger and an injection pump. An oil and/or gas separator is optional. In some cases, anti-scaling prohibitors may be required. Safety measures like a blow-out prevenator and double tubing to avoid and control gas leakage have recently become mandatory in the Netherlands. To date all existing geothermal projects are situated in the horticultural sector, although some proposals exist for projects in the built environment. A heat network or a heat distribution network may be required, but is not part of this factsheet.

Legend: 1) above ground installation ; 2) production and injection wells; 3) brine extraction and injection.

Downloads

Geothermal heat production, deep, (>1500 < 4000 meter)Gerelateerde publicaties

Industriële vraagrespons: groot potentieel, beperkte operationele inzetbaarheid

Wat industriële vraagrespons wel en niet kan betekenen voor leveringszekerheid richting 2030

Flexibiliteit op bedrijventerreinen

Een toekomstverkenning van het potentieel van energieassets

Kosten hernieuwbare energie verrassend vergelijkbaar voor Nederlandse en Saoedi-Arabische industrie

Comparison of future cost of renewable energy between regions