Main components

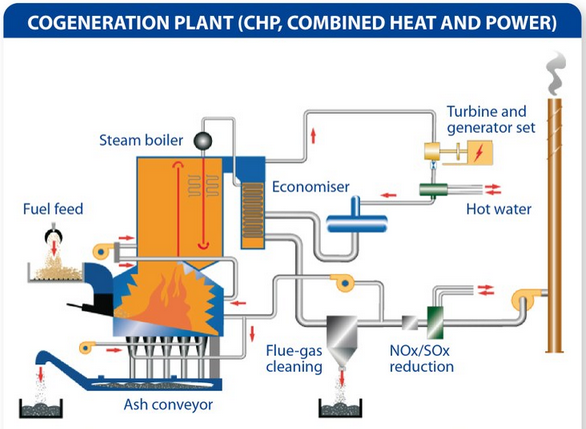

Components of a coal-fired power plant for the production of electricity and district heating typically consist of fuel storage/fuel feed , steam boiler, economiser/heat exchanger (i.e. feedwater heaters; commonly used as part of a heat recovery steam generator in a combined cycle power plant), turbine and generator, cooling technique, flue gas cleaning equipment and ash conveyor.

Energy production related aspects

The downside of utilizing heat for district heating is that the electrical efficiency of the CHP plant is lowered (loss of electricity production) (ECN, 2011). Loss of electricity production (GJe/GJth supplied) depend on the temperature of heat disconnection. Typical losses are included in this factsheet.

Coal-fired CHP plants are equipped with flue gas cleaners to limit/prevent emissions of various harmful substances (such as particulate matter, NOx, SOx). The flue gas cleaner is included in the costs presen ted in this factsheet.

All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).