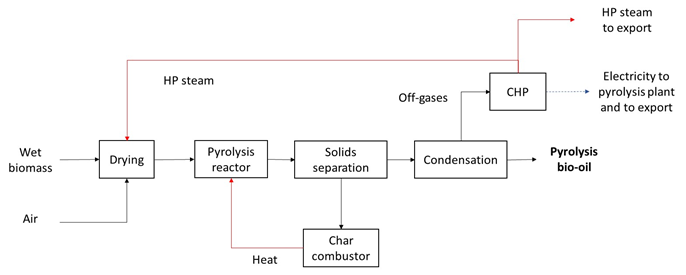

Solid biomass is milled to particle size below 3 x Y x Z mm to allow high conversion (BTG-BTL, 2020), dried to low moisture content (5-10%) and exposed to high temperature (approx. 500˚C) without oxygen. In the reactor, the particles are mixed with hot sand, which is used as a heat carrier, and the pyrolysis occurs around 500°C (JRC,2019). The resulting products are: pyrolysis bio oil (liquid), biomass char (solid) and residual gas; the last two are separated from the oil by cyclones and condenser. The sand is recycled back to the reactor. Char is used to provide heat to the pyrolysis reactor and the residual gas is typically used to generate electricity and heat via a CHP unit. The energy generated is normally sufficient to meet the energy demand of the drying process and the surplus can be exported.

All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).