All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).

Geothermal heat production, ultradeep (> 4000 meter)

Geothermal heat production, ultradeep (> 4000 meter)

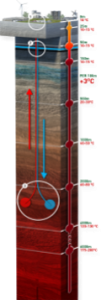

This technology represents an application of geothermal heat production which is currently (2020) not yet applied in The Netherlands. The main characteristic is the depth from which one expects to extract hot water : deeper than 4000 meter, hence the name Ultra Deep Geothermal energy (UDG). A typical project exists of two wells, a production and injection well, also called doublet. The wells are or fully vertically drilled or vertical with a curvature deep below. The bottom of the wells is situated in a water holding layer of limestone, called Dinatien, and lies deeper than 4000 meters (6000 to 8000 meters on average) below ground level. Salty hot water (brine) under pressure is pumped up through the production well by an ESP (electric submersible pump), cooled in a heat exchanger and injected back in the same layer through the injection well. In principle there is no loss of water, but some degassing may be needed as natural gas or oil needs to be separated from the brine. The estimated production temperature varies between 120 and 140⁰C and makes this technology suited for low temperature steam supply for industry. Production rates can vary but are estimated to be lower than the deep geothermal heat projects (few hundreds m3/hour). Subsurface stimulation of the well to increase water volumes is supposed to be part of a typical project. The use of advanced materials to prevent scaling or gas leakage may be required. The installation further consists of a production pump, and oil and/or gas separator, an above ground heat exchanger and an injection pump. A heat network or a heat distribution network is not part of this factsheet.

If the return temperature after the first user (industrial steam) would still be relatively high, the geothermal heat could be further used in a cascading application where the first (industrial) user is followed by a second heat exchange with a low temperature user (50-70⁰C) with a similar or sufficient amount of full load hours (e.g. horticulture). By this, the injection temperature could be further lowered (to 35⁰C or lower), increasing the heat power of a UDG project.

Legend: 1) above ground installation ; 2) production and injection wells; 3) brine extraction and injection.

Downloads

Geothermal heat production, ultradeep (> 4000 meter)Gerelateerde publicaties

Industriële vraagrespons: groot potentieel, beperkte operationele inzetbaarheid

Wat industriële vraagrespons wel en niet kan betekenen voor leveringszekerheid richting 2030

Flexibiliteit op bedrijventerreinen

Een toekomstverkenning van het potentieel van energieassets

Kosten hernieuwbare energie verrassend vergelijkbaar voor Nederlandse en Saoedi-Arabische industrie

Comparison of future cost of renewable energy between regions