The following journey describes a collaboration between a company and their technology supplier. This journey illustrates a common bottleneck of too much caution and assumptions made by the technology supplier. Technology suppliers can be reluctant to include a more energy efficiency solution in their quotation out of fear of losing the quotation process on price.

The client in this journey is commonly known for their awareness of sustainability. The technology supplier is also aware of this, as they have collaborated in a previous project. Yet, when asked to provide a solution for their new transportation line, the technology suppliers does not offer the sustainable option first. This is only brought up later in the collaboration, when the decision has already been taken and the engineer of the company explicitly asks whether there are more possibilities in terms of energy efficiency. Without that demand from the company, the more energy efficient solution would never have emerged as an option.

This real-life example shows that it is still up to the client to challenge their technology suppliers, because the technology suppliers will not offer energy efficiency options by themselves. Technology suppliers will only do this once they notice they are losing projects because they score badly on energy efficiency compared to competitors. For clients, it is therefore not sufficient to include sustainable innovation as an ‘optional component’, since suppliers can be reluctant to include this in the quotation out of fear of losing the quotation process on price. This journey also emphasizes the need of acquisition of new skills on how include the topic of sustainability in dialogues with clients.

Context

- The company is a large multinational in the fast-moving consumer goods industry.

- A key asset of the company is its corporate image of social responsibility. To ensure their impact, the company has a sustainability plan with which it aims to develop new business practices that are beneficial for both the company and its stakeholders. The overall ambition, as expressed by the company’s CEO, is to double the size of corporate revenues while reducing the associated environmental footprint and increasing the positive social impact.

- Sustainability is also an important element in the company’s procurement function. In the words of Petra, one of the procurement managers, the company “is setting the standard” in this respect. There is a growing awareness of the importance of a variety of sustainability issues (e.g. energy savings, waste reduction) in capital investment projects. However, as energy is only a small part of the whole chain, the purchasing team finds energy efficiency not nearly as important as, for example, raw materials. As a result, while the company does see value in more energy efficient solutions, in practice, it comes down to the project managers in the company to ensure energy efficiency is taken into account.

Phase 1: Awareness & motivation

- One of the company’s plants manufactures a variety of ice cream products. Since product volume has steadily been growing in the past years, investments in additional capacity are needed.

- Part of this investment is the replacement of the internal transportation system that transfers the products through the factory from freezer to packaging. The aim is to speed up the existing line from 220 to 440 products per minute.

Phase 2: Market orientation

- The bidding process is led by Christina, the company’s project delivery engineer, and her team. The company works with a list of preferred suppliers as this helps to limit the risk, to make better price arrangements and to take advantage of the economies of scale. Multiple suppliers from the list are asked to participate in the bidding.

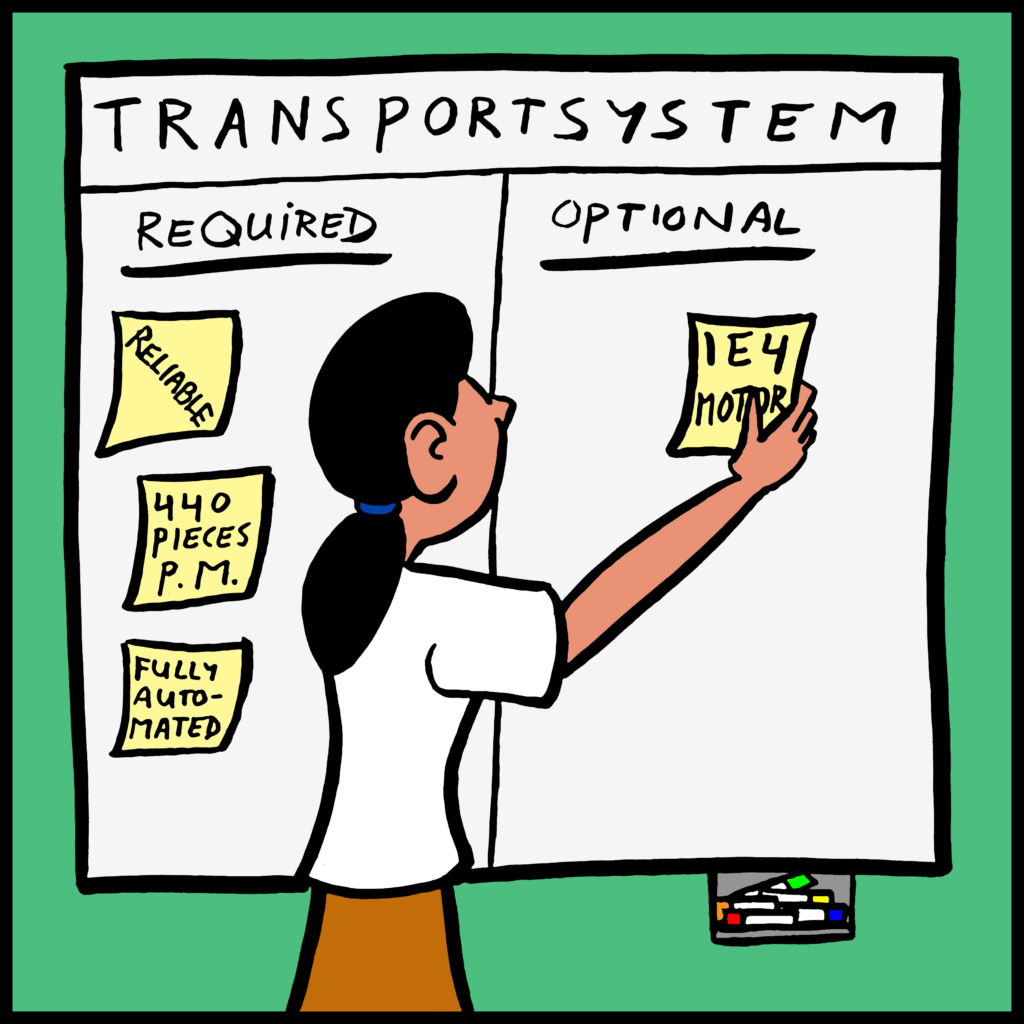

- The main project purpose is to provide a reliable, fully automated and integrated transport solution that speeds up the existing line from freezer to packaging. To find the best solution, Christina formulates requirements.

- One of the requirements for this investment project covers sustainability. Energy use is one of the required components in supplier quotations, indicating a preference of using energy efficient motors (IE4 efficiency class) and other components. In addition, sustainable innovation is listed as an “optional component”, aiming to encourage suppliers to develop improved processes to advance on the company’s overall environmental impact and performance.

Phase 3: Choosing a solution

- With approval of the head office, Christina chooses one of the preferred suppliers for the transportation project based on positive previous experience. This supplier had already been involved in the implementation of transport lines in the same plant some years ago, and has provided the necessary services since then.

- Theo is the project manager of the technology supplier. Christina and Theo report an excellent working relation. When asked for the reasons, Theo indicates he does not know exactly but he does express enthusiasm about the fact that both of them grew up in the same region and are fanatic supporters of the same football club.

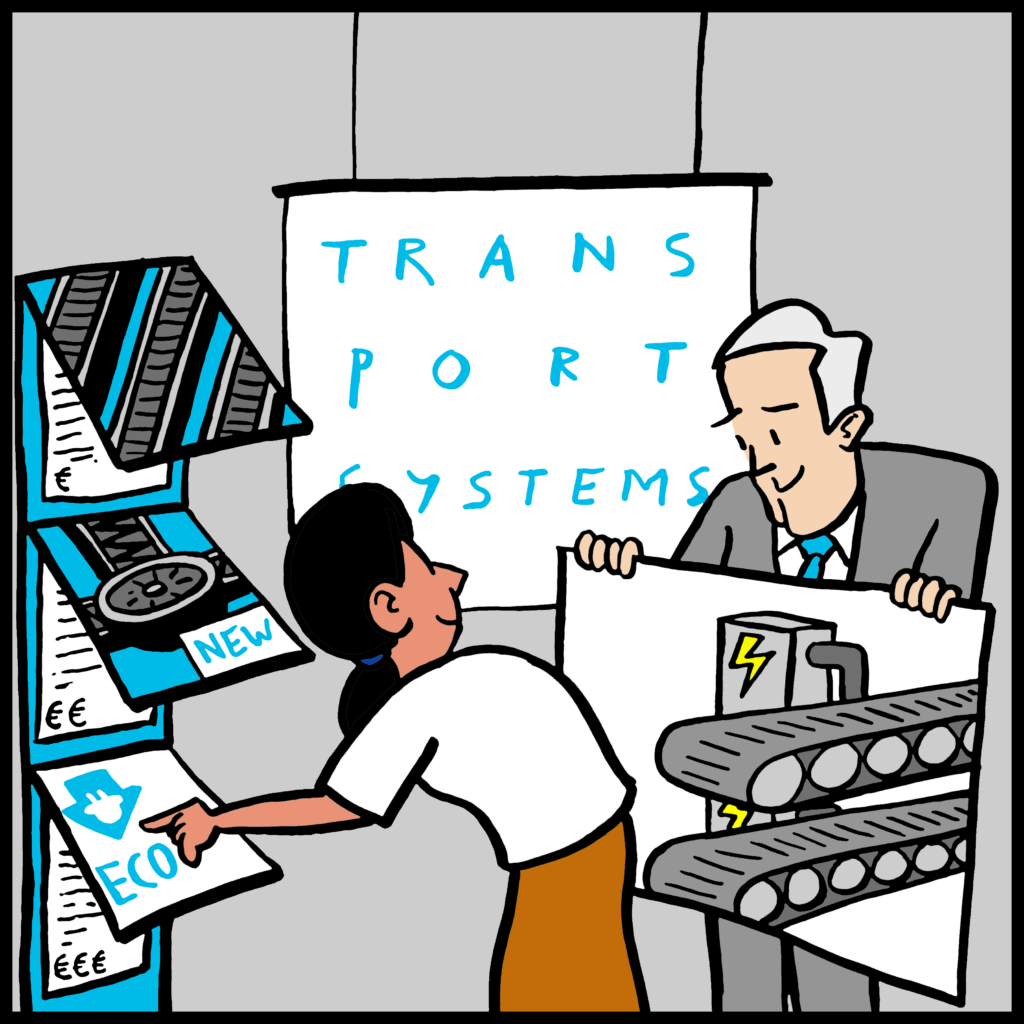

- Theo initially offers the supplier’s standard solution which is not its most energy efficient one. Theo and his colleagues perceived that offering the standard design would put them in a better position to win this order as it is cheaper. The technology suppliers mainly complete with their prices.

- After winning the order and having agreed on the price, Christina meets with Theo, and asks him if they could also implement a more energy efficient solution. This is indeed the case, but the more energy efficient solution would be more expensive. It was therefore not included in Theo’s initial bid, and only raised by Christina’s request.

Phase 4: Financing

- Despite the higher investment costs, Christina would like to implement the more energy efficient transportation solution, so she explores her financial options. Calculations made by Theo show that the payback time for this new solution would be about three years. For this company, three years is an acceptable payback time, so the only remaining issue to solve is the price difference.

- For projects aimed at increasing capacity, a project manager (such as Christina) is allowed to overspend the budget by 10% to make an extra investment to obtain a more energy efficient solution. She can use this 10% without consulting headquarters, as long as she can motivate the investment and it fits in the overall budget.

- On top of that, Christina knows that the company has dedicated sustainability funds. As Petra from purchasing explains, these funds ‘may effectively decrease the payback time of sustainable investment projects’. Not all project delivery engineers know how to get access to this sustainability fund, and one has to know the processes of the company pretty well. As Christina has experience with such investment projects, she can manage access to these funds. She does admit, however, that it is difficult to decide when a project may be classified as a “sustainability project”. So she does not always take this financing route. This case of the internal transportation system was also a ‘regular’ project.

- In the end, using the sustainability funds is not necessary as the supplier (Theo) offers to pay the extra investment costs for the more energy efficient solution.

Phase 5: Decision making

- With permission of the head office, Christina makes the decision to invest in the new, more energy efficient type of motor for the transportation project. This decision is mainly influenced by the strategic vision in which sustainability plays a major role, and the corporate payback criteria.

- As the more energy efficient option is also more expensive, Theo of the supplier decides not to charge the difference to the company. His incentive is that this project grants his company the opportunity to showcase a project with new technology.

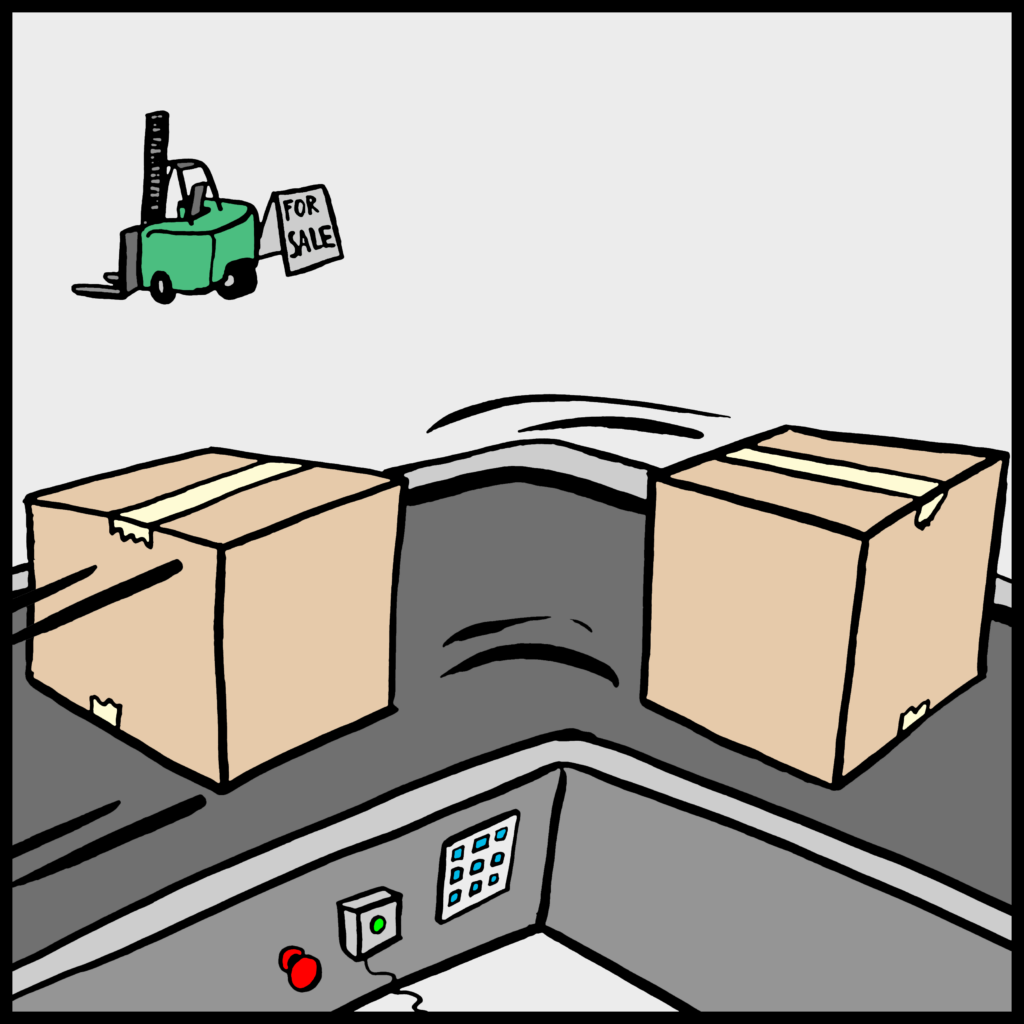

Phase 6: Installation and use

The innovative, more energy efficient transportation solution is implemented in the company’s process line, and with great success. In following projects of the company, they would choose the same solution more often.