This journey revolves around the interactions between a company and an energy advisor. Companies can hire an energy advisor for conducting short consultancy projects to identify the energy efficiency options for industrial locations. Additional, energy advisors can help the client understand the current regulations and how the company can comply with them. For energy advisors, discussing with their clients about how they perform their primary tasks is not a common practice. Many clients are not open to feedback from external advisors on their processes, because generally, they regard themselves as more knowledgeable about their processes than external advisors. Therefore, advisors are reluctant to discuss their clients’ processes. The described journey below is quite unique as the energy advisor has dared to bring up the process in the conversation anyway, and in doing so, he managed to make a convincing case to the clients. The trust between the owners of the company and the energy advisor was essential in this case.

Context

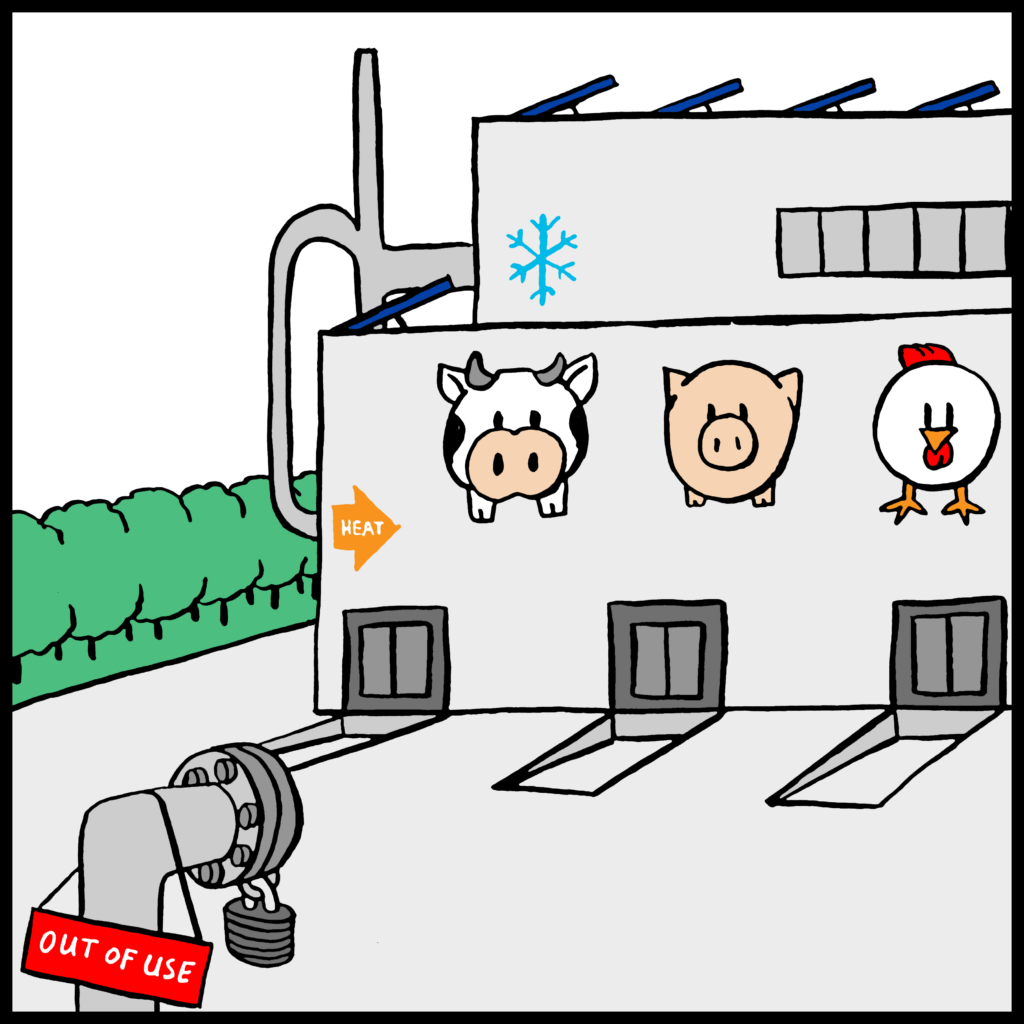

- The company produces beef which is supplied to food chain restaurants, food services, and processing industries. The end product is vacuum-packed beef cuts.

- In the last years, the sector has been remediated twice and many companies have been unable to keep up or have postponed investments.

- The company is owned and run by a family, that invests “their own money” in the company. This creates a powerful mindset with a long-term vision (horizon of 25 years) and its resources are spent accordingly (instead of focusing on “quick wins”).

- The company does not have a specific vision or policy related to ecological sustainability.

Phase 1: Awareness & motivation

- Olivier and Caroline, the owners of the company, want to modernize their company by building a new factory. The main motivators are improving the quality of their products, increasing the production capacity, and creating a healthy family business in the long run.

- Part of this investment project is a cooling system for the new factory.

Phase 2: Market orientation

- Olivier and Caroline hire an external advisor, Edward, with expertise in energy and processing at the very start of the project. Edward sees it as his role to ensure “an equal power balance between client and supplier regarding expertise”, and also to make “the clients think for themselves” instead of fully relying on the expertise of suppliers. Due to, amongst other things, Edward’s extensive expertise, he had the full trust of Olivier and Caroline.

- Edward plays a significant role in the design of the new factory. He supports Olivier and Caroline by providing information, enabling them to define the essential requirements together and make a concept design. Five parties are approached, and three of them are asked to make an offer based on the concept design.

- The main themes in the project – and requirements for the offers – are building for the future and cost effectiveness. When Edward introduces the concept of energy efficiency as a cost-saving method, Olivier’s and Caroline’s interest in sustainability increases. Up to that point, compliance with the governmental Energy Efficiency program (Meerjarenafspraken energie-efficiëntie, MJA) was the main incentive for energy saving policy within the company.

- The main themes in the project – and requirements for the offers – are building for the future and cost effectiveness. When Edward introduces the concept of energy efficiency as a cost-saving method, Olivier’s and Caroline’s interest in sustainability increases. Up to that point, compliance with the governmental Energy Efficiency program (Meerjarenafspraken energie-efficiëntie, MJA) was the main incentive for energy saving policy within the company.

Phase 3: Choosing a solution

- The offers are evaluated on their fit to the requirements. Based on Edward’s advice, Olivier and Caroline select the supplier with the most expensive offer. The main reason being the supplier’s proactive attitude to the project. Sven, the engineer and account manager of the technology supplier, took the concept design as a starting point and added own ideas, thereby developing an unique concept.

- Sven’s proposal involves an energy efficient cooling system, which enables the company to get BREEAM[1] The installation of such a system reduces their use of natural gas. Subsequently, the surplus of energy can be used for heating water or heating the office space. For the BREEAM certification, the new slaughterhouse would achieve a score of 4 stars (out of 5).

- Sven (technology supplier) had no prior business relationship with the company. He recalled that Olivier and Caroline were open to new solutions. Open collaboration and trust played a role in choosing the best options and noticeably “the advisor and the company were fully open for other suggestions,” observed Sven. However, the company was a new customer for the supplier, hence it was more difficult to raise the issue of energy efficient solutions. The challenge was to define specifications based on the concept made by the external advisor and “ask about the underlying motives.” The external parties involved in the project had different impact on the decisions. Sven noted that “they trust an independent advisor, although sometimes it is not true what he says (…) but they do not believe our installers (…) who are suspected of self-interest.”

- The role of the external advisor was quite unique to consultancy projects such as these. Due to, amongst other things, the background of the advisor, he had the full trust of Olivier and Caroline. Through this background, he has acquired extensive expertise in energy efficiency and processing.

- Moreover, Edward was already familiar with Sven’s company, which has good references from other parties in the sector when it comes to reliability, maintenance and service.

Phase 4: Financing

- Although the investment of this energy efficient solution is higher, Olivier and Caroline not only look at the purchase costs but also take the usage and the maintenance of all the equipment into account (total cost of ownership, TCO).

- They expect the investments to pay off in the future. As they mention themselves: “We are a family company that has a long-term focus; we are the only shareholders so we do not have to convince anyone. However, you start hesitating whether investments that span over 8-9 years should be carried out.”

Phase 5: Decision making

- As the more energy efficient cooling system will save costs in the long run, Olivier and Caroline decide for this solution. To account for the high initial investment costs, they set up a maintenance contract with Sven. They sign a 10-year service agreement.

- This decision is made by Olivier and Caroline, based on Edward’s advice. During the process, Edward has been in close contact with Olivier, Caroline and Sven, and supported them through the whole process from the start.

Phase 6: Installation and use

- The construction works are executed. In the new factory, no natural gas is used anymore to cool or heat the interior. Solely the new cooling system is sufficient, and over-engineering is avoided.

- Both the owners of the company (Olivier and Caroline) as the energy advisor (Edward) are satisfied with the project, and even call it a “best practice”.

- This project leads the way to sustainability as a central theme in the company strategy, and opened the door for an energy saving policy within the company.