Working of the Technology

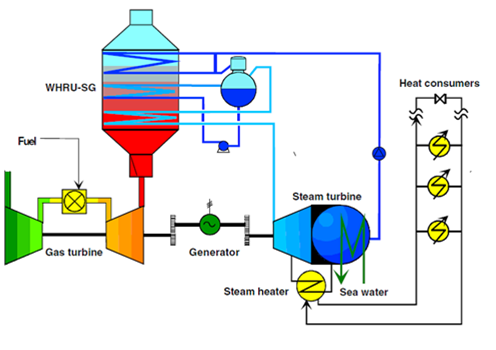

A ‘modern’ natural gas-fired power plant can be a combined heat and power plant (CHP). In case of a combined cycle gas turbine/CCGT (Dutch: Stoom en Gasturbine/STEG) there is a gas turbine and steam turbine. In the first turbine, gas is expanded to drive the turbine. The second turbine, a steam turbine, is being driven by the residual heat of the gas turbine. Water is evaporated using heat from the waste heat recovery unit steam generator (heat exchanger) to produce high pressure steam which is expanded in a steam turbine to generate electricity using a generator. From the drain of a steam turbine, heat can be fed into a heat distribution network. Heat can be supplied to different sectors such as the built environment or industry. This factsheet focuses on a CHP plant that delivers heat to the built environment. A CHP plant without carbon capture and storage (CCS) is considered in this factsheet.

Main components

Components of a gas-fired power plant for the production of electricity and district heating typically are an (inlet) air compressor, gas turbine and generator, economiser/heat exchanger (i.e. feedwater heaters; commonly used as part of a heat recovery steam generator in a combined cycle power plant), steam turbine(s) and generator, condensor, cooling technique, and flue gas cleaning equipment.

Energy production related aspects

The downside of utilizing heat for district heating is that the electrical efficiency of the CHP plant is lowered (loss of electricity production) (ECN, 2011). Loss of electricity production (GJe/GJth supplied) depends on the temperature of heat disconnection. Figures about losses are included in this factsheet.

Besides CO2 emissions, a STEG also emits NOx (Ecofys, 2014). A power plant is equipped with flue gas cleaners to limit NOx emissions. The flue gas cleaner is included in the costs presented in this factsheet.

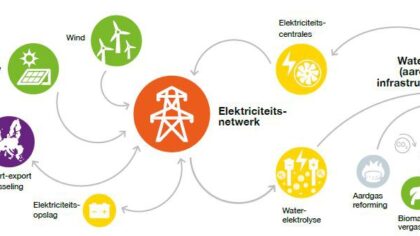

All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).