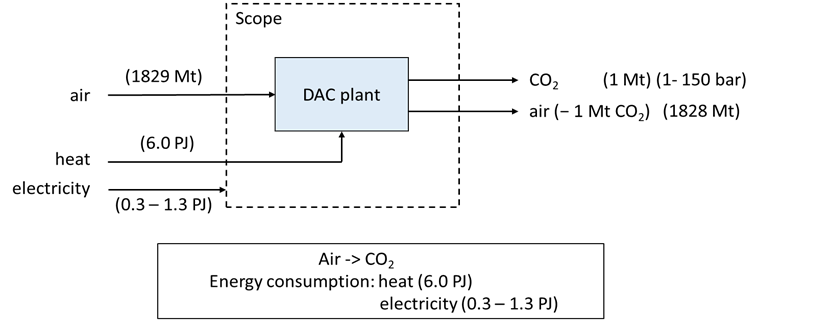

No large scale commercial plants exist today and pilot plants vary significantly in their process design. We here describe the plant very basically, without a strict technology design, and use average values for costs and energy use. We here assume that the produced CO2 is 100% pure, although in reality the product may contain traces of other gasses and H2O.

From website Climeworks: “Our plants capture atmospheric carbon with a filter. Air is drawn into the plant and the CO2 within the air is chemically bound to the filter. Once the filter is saturated with CO2 it is heated (using mainly low-grade heat as an energy source) to around 100 °C (212 °F). The CO2 is then released from the filter and collected as concentrated CO2 gas to supply to customers or for negative emissions technologies. CO2-free air is released back into the atmosphere. This continuous cycle is then ready to start again. The filter is reused many times and lasts for several thousand cycles.”

From the website Carbon Engineering (CE): “Our DAC technology has four major pieces of equipment. The process starts with an air contactor, which is a large structure modelled off industrial cooling towers. A giant fan pulls air into this structure, where it passes over thin plastic surfaces that have potassium hydroxide solution flowing over them. This non-toxic solution chemically binds with the CO2 molecules, removing them from the air and trapping them in the liquid solution as a carbonate salt. The CO2 contained in this carbonate solution is then put through a series of chemical processes to increase its concentration, purify and compress it, so it can be delivered in gas form ready for use or storage. This involves separating the salt out from solution into small pellets in a structure called a pellet reactor. These pellets are then heated in our third step, a calciner, in order to release the CO2 in pure gas form. This step also leaves behind processed pellets that are hydrated in a slaker and recycled back within the system to reproduce the original capture chemical.”

All information in the datasheets is also available in ESDL (Energy System Description Language). You can find them in the Energy Data Repository (EDR).